Kent USA stands at the forefront of precision engineering, providing world-class CNC machines and Manual tools built for performance and longevity. From Milling and Turning to Grinding and Fabrication, our solutions are trusted by manufacturers across industries to deliver consistent accuracy and efficiency.

Kent USA offers a comprehensive range of precision machine tools designed for performance, reliability, and long-term durability. From advanced CNC lathes and milling centers to grinding machines and manual tools, our products deliver consistent accuracy and efficiency. Trusted by industries worldwide—such as aerospace, automotive, and general manufacturing—Kent USA machines empower businesses to achieve superior productivity and quality with every operation.

Kent USA stocks manual hand feed surface grinders with a working capacity of 6” x 18” to 10” x 20”. Table ways use hardened steel linear rails with precision balls for smooth and effortless hand feed.

Designed for high-volume production and intricate finishing operations, these grinders feature intuitive operator controls, automated 2- or 3-axis movements, and robust hydraulic table drives that ensure smooth, consistent performance across a diverse range of workpiece sizes—from compact 8” x 18” tables ideal for small parts to expansive 34” x 128” models suited for large-scale components in aerospace, automotive, and tool & die industries.

Kent USA offers high-performance surface grinders equipped with SD (Simple Digital) and PNC (Programmable Numerical Control) controls, delivering precision, efficiency, and ease of use for various grinding applications.

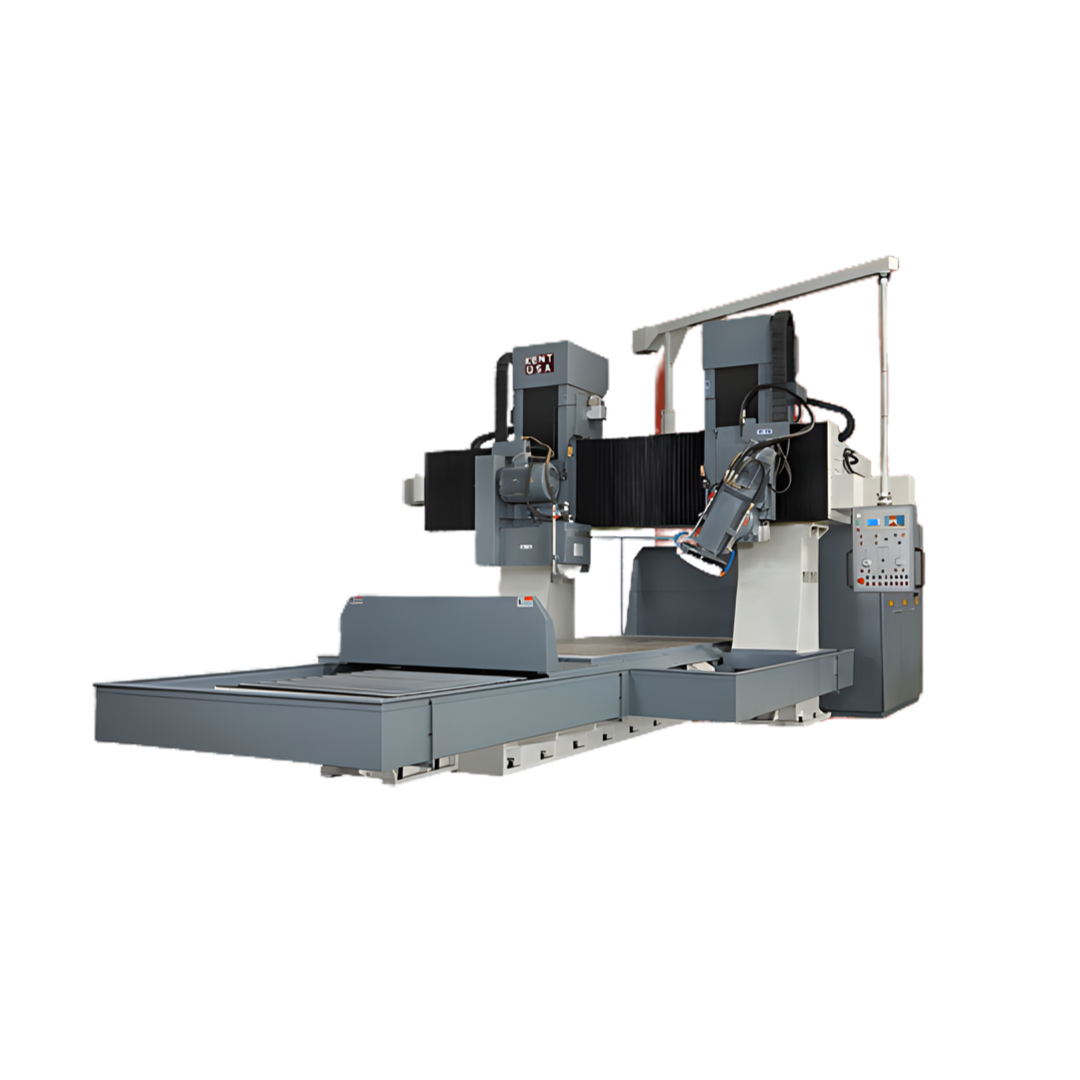

Kent USA Double Column Surface Grinders is a large, heavy-duty fixed-beam surface grinders, well-suited for large die-mold applications and high precision grinding of machine bases and ways.

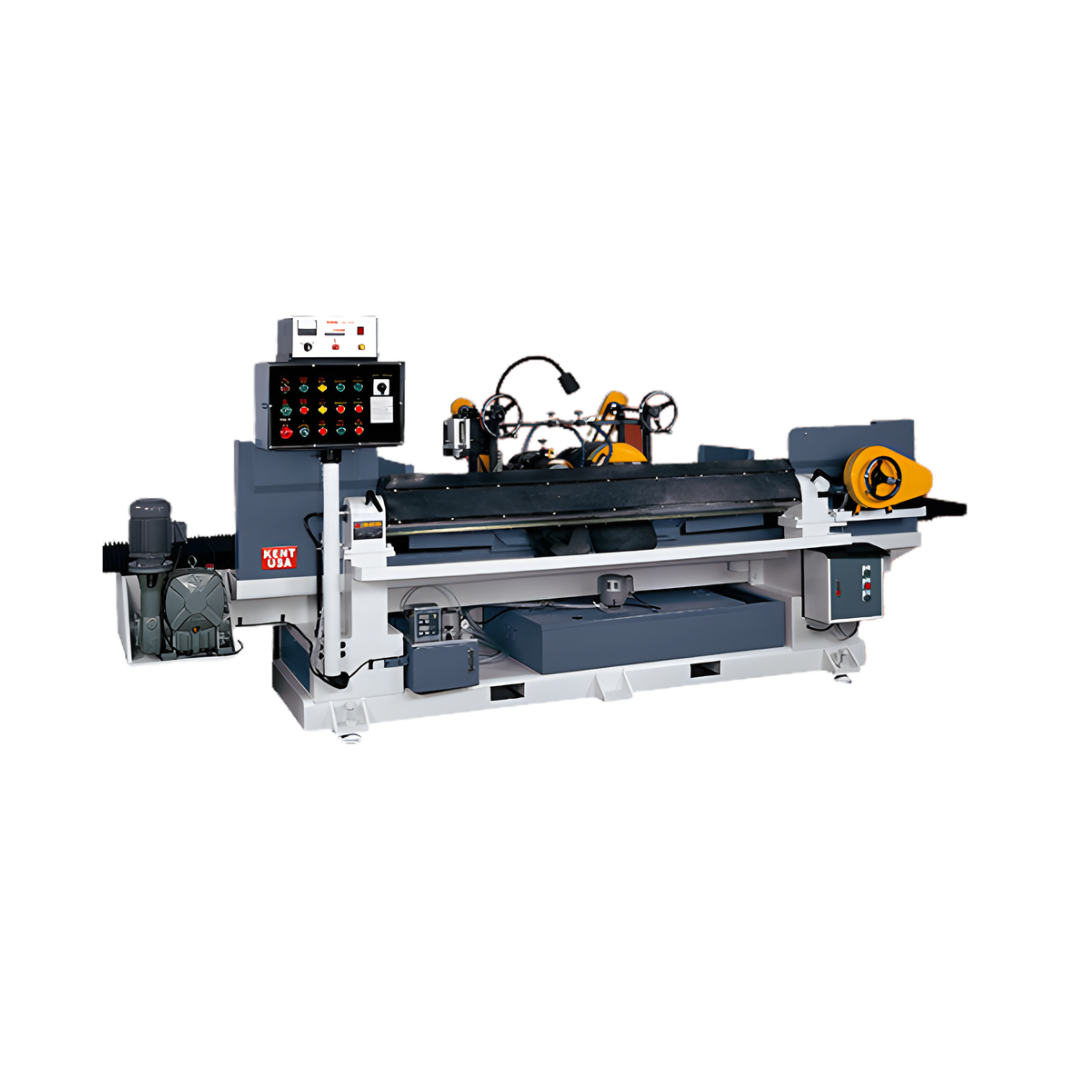

For high-volume production runs and generating rapid rounding and accuracy, Kent USA features a line of Centerless Grinders. The machines in this collection allow for very tight dimensions and roundness tolerance controls.

The machines in this collection allow for very tight dimensions and roundness tolerance controls. Kent USA Cylindrical Grinders are capable of grinding pieces of up to 13″ in diameter.

These grinders feature fine grinding by variable speed motor to optimize grinding of high-speed steel knives or carbide knives. Dual coarse and fine grinding wheels allow for grinding efficiency and fine finish.

Tool & Cutter Grinders line offer precision and reliability and are perfect for sharpening milling cutters and tool bits as well as other cutting tools. These machines are engineered for maximum accuracy and minimal downtime.

Rotary Grinders are capable of working on hard, brittle metal, and mold materials. Our rotary grinders are built with Meehanite Class FC 30 casting for high rigidity and wear resistance, maintaining operation accuracy.

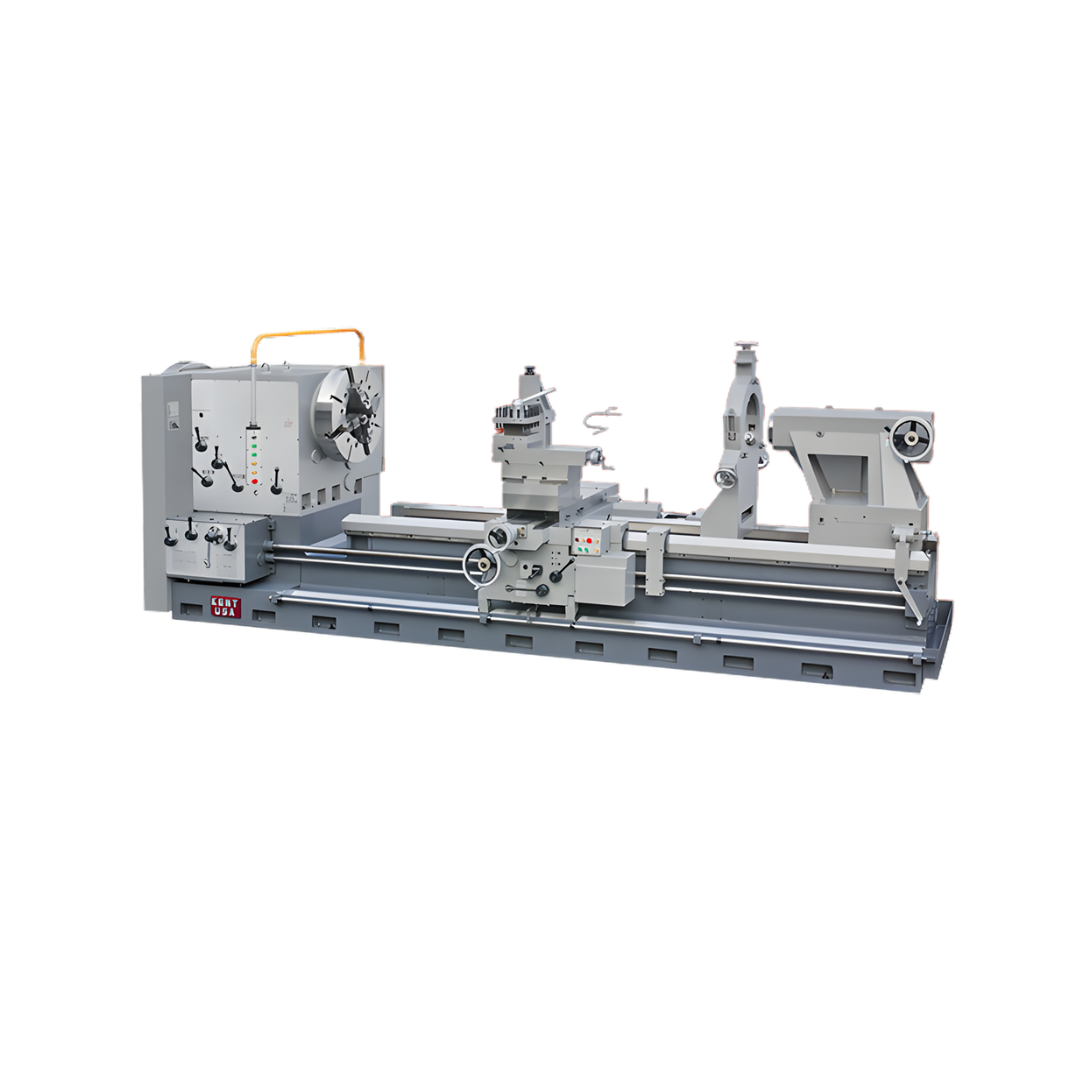

Manual Economy Lathes put the same Kent USA reliability and precision within reach. Our economy lathes offer the same quality engineering and reliability for your regular day-to-day turning.

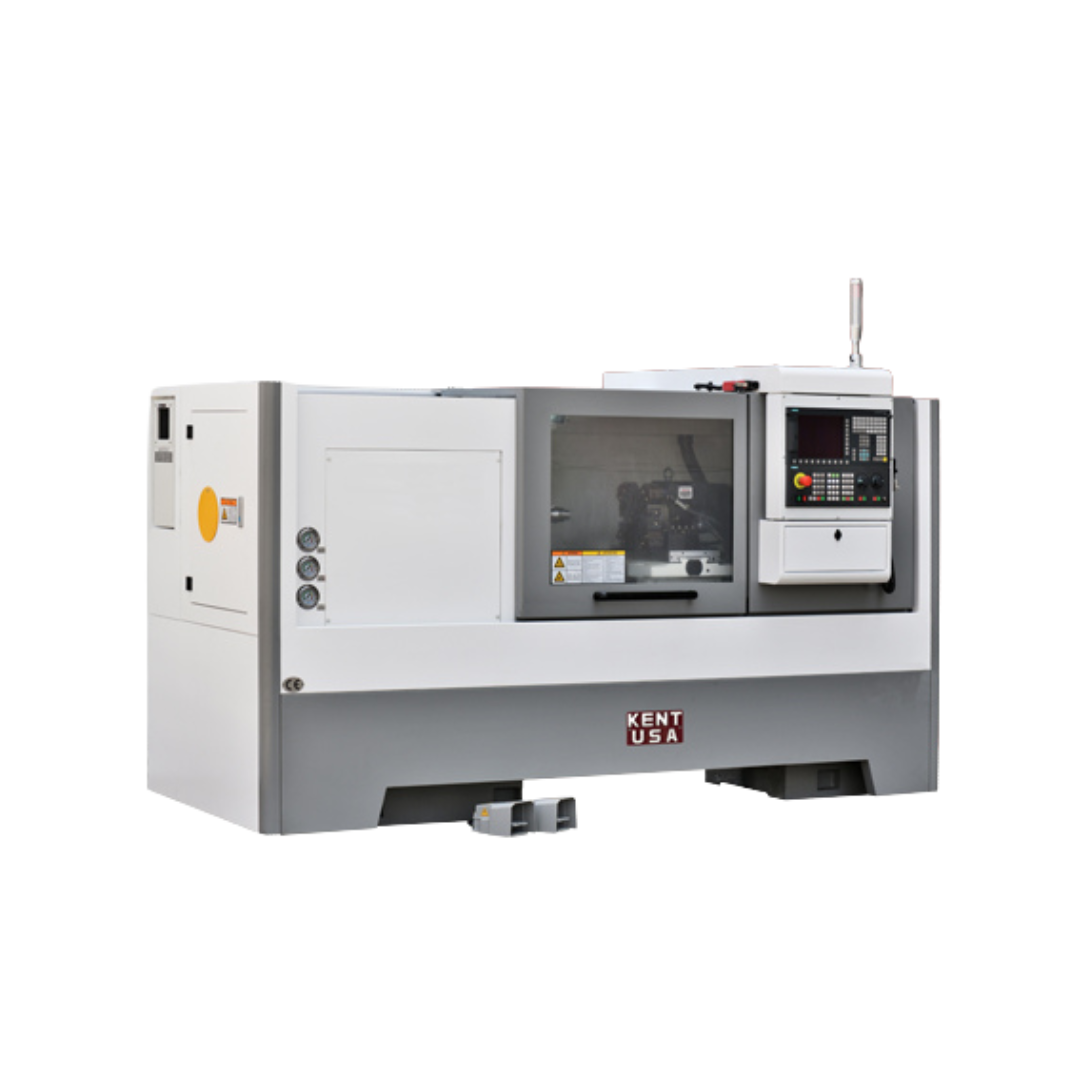

The Kent USA CNC Precision Teach Lathes offer you dependable, accurate, high-precision machining with efficient CNC technology. These machines provide maximum accuracy and minimal downtime.

Ideal for turning large workpieces in the oil field industry, these powerful machines can easily accommodate large diameter turning and threading applications.

Hilman Traksporter is a remote controlled self-propelled crawler system designed to move heavy machinery or other heavy objects safely, easily and efficiently.

The Kent USA CNC Precision Teach Lathes offer you dependable, accurate, high-precision machining with efficient CNC technology. These machines provide maximum accuracy and minimal downtime.

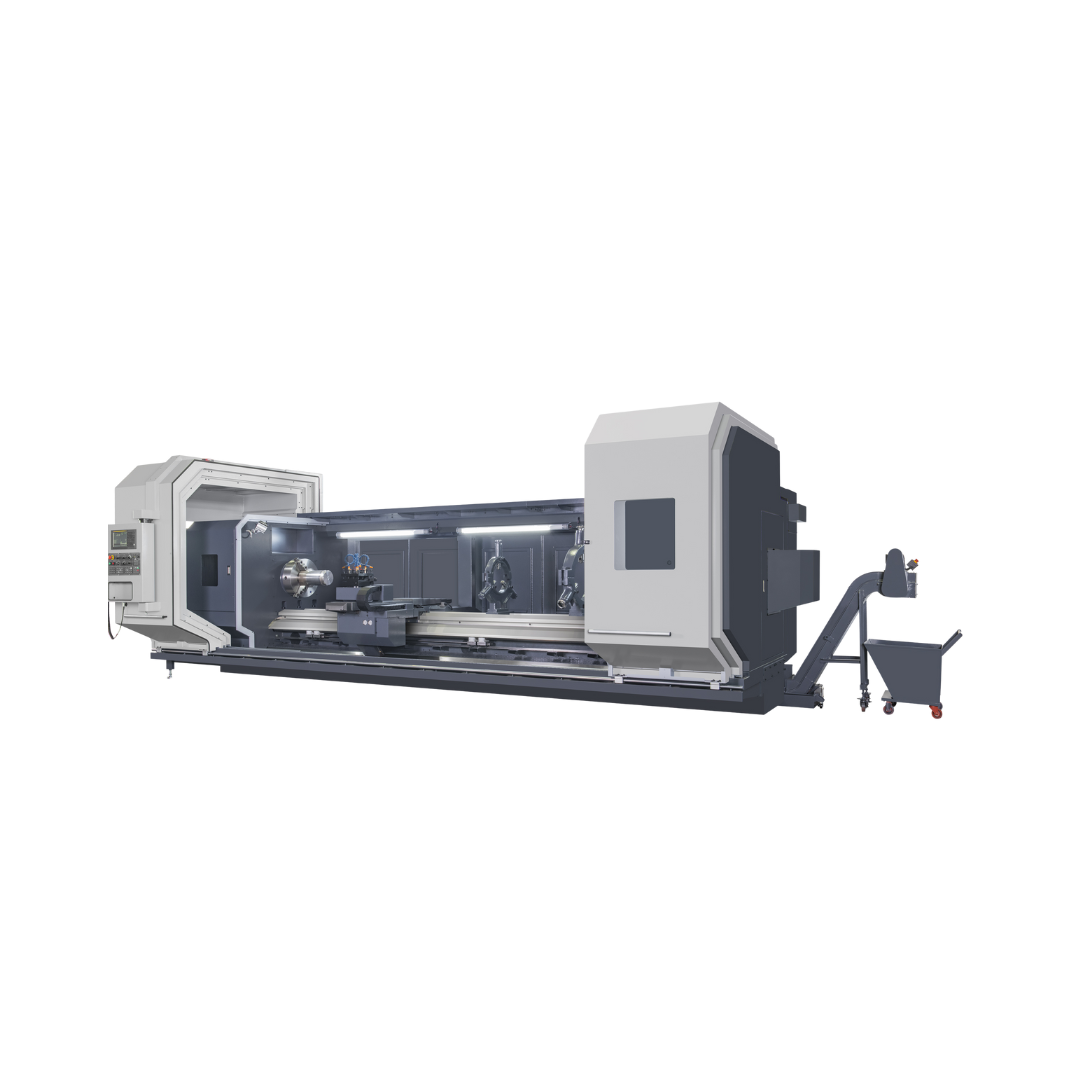

The Kent CNC Heavy Duty Boring Turning Center Series provides 2 excellent configurations for heavy duty turning for large parts.

Our manual knee mills are ideal for prototype, tool room and R&D work, as well as part of training programs and everyday machining. You will be able to perform practically any milling operation on a knee mill.

Our industry-leading CNC knee mill with the Acu-Rite MillPWRG2control brings powerful CNC capabilities to the tool room with easy-to-learn conversational programming and advanced canned cycles to empower everyone on the shop floor for greater productivity.

CNC Bed Mills & Vertical Machining Centers offer more rigidity and travel. These are geared towards facilities that require high-production capacity with high speed and accuracy

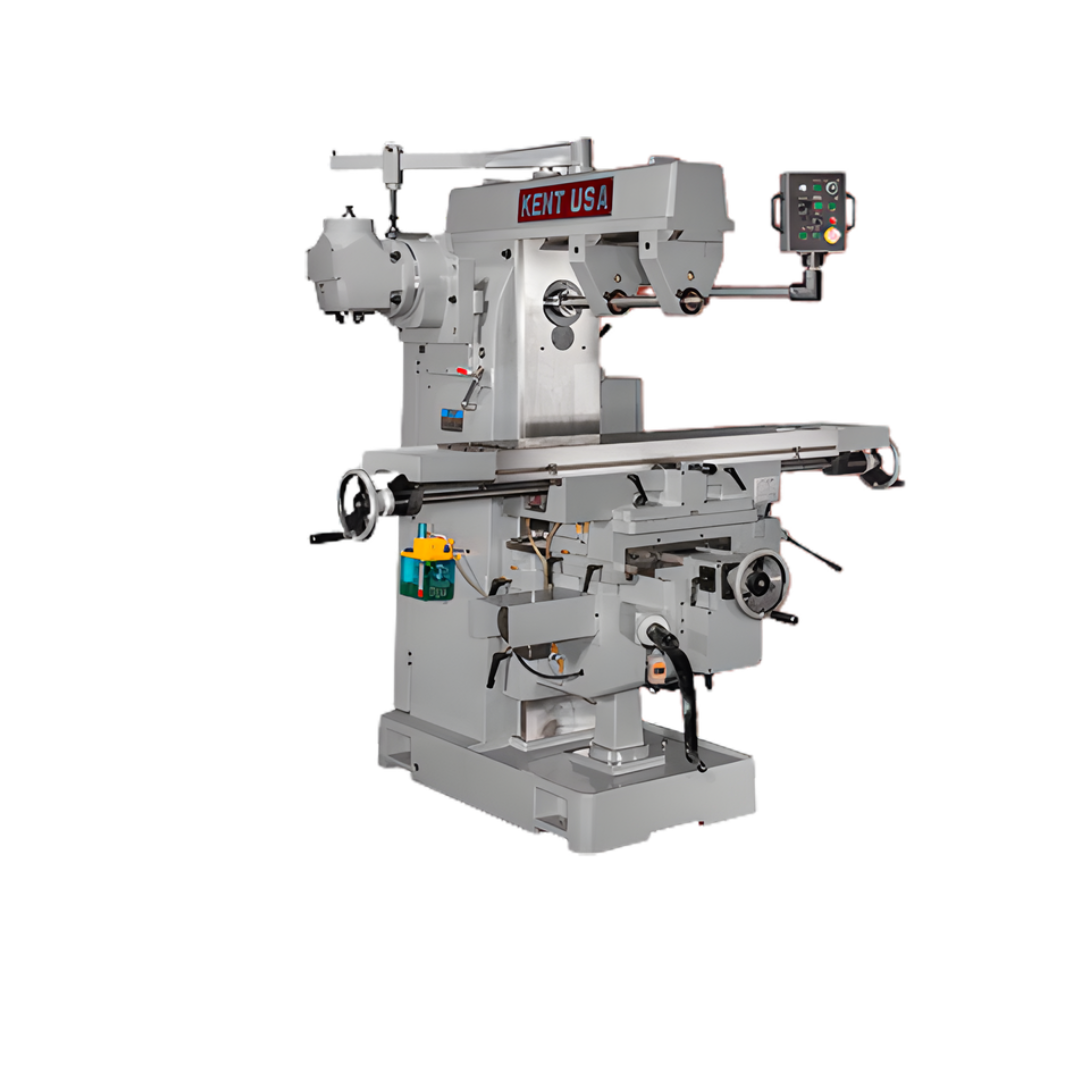

Kent USA Combo Horizontal/Vertical Mills offer both the capabilities of a Vertical Mill and a Horizontal Mill in one design.

Kent USA’s line of Universal Mills provides a wider range of possible tool paths and a balance of high production capacity and precision accuracy.

Kent USA’s collection of Horizontal Boring Mills incorporate many features from various machine tools and offer high precision and great stability in heavy-duty cutting.

If (stud)bolts are to be reused, cleaning is absolutely necessary. Also the VCI guideline for flange assembly also requires that bolts be to new condition before reassembly. In order to clean bolts in the shortest possible time, we have developed the BoltClean Machine.

Kent USA Flushing Type Wire EDMs can cut plates as thick as 300 mm and are ideal for creating punches, tools and dies from exotic hard metals that are difficult to machine with conventional methods.

Kent USA Wire EDM Submerge Type are excellent at maintaining stable part and lower arm, fixture and worktable temperatures and thus resulting in straighter, more accurate cuts.

© 2026 Boltimizer Corporation. All rights reserved.