At PROTEM, we deliver state-of-the-art portable machining solutions designed for precision, reliability, and operational efficiency. Our services include advanced orbital cutting and beveling, flange and valve facing, on-site equipment rental, and expert technical support. We empower industries such as energy, shipbuilding, and manufacturing to achieve seamless maintenance and fabrication with unmatched accuracy and safety.

PROTEM delivers advanced portable machining solutions designed for precision, reliability, and efficiency. From orbital cutting and beveling machines to flange and valve facing tools and on-site portable equipment, our products provide real-time performance, accuracy, and safety or industries worldwide, including energy, shipbuilding, and manufacturing.

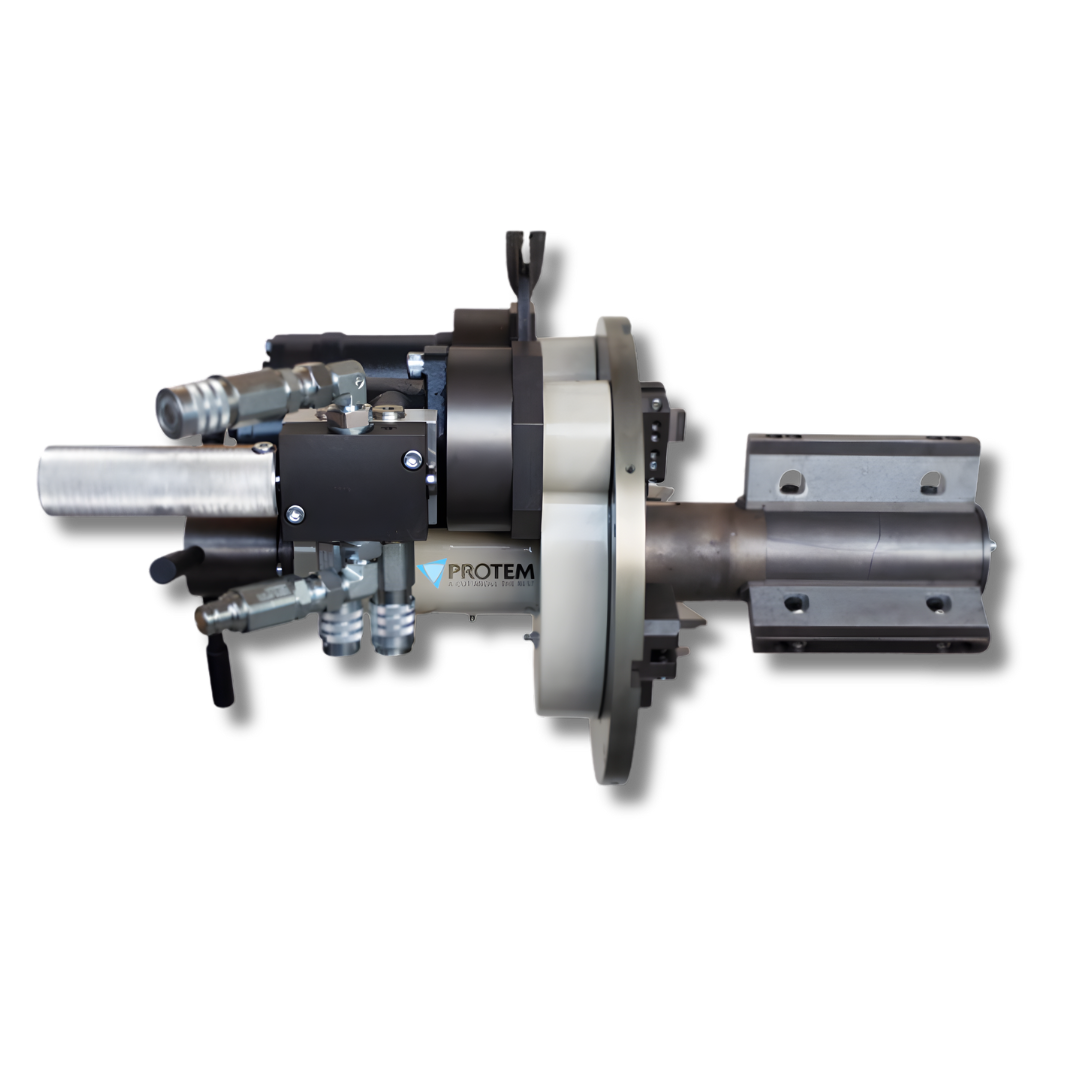

The machining capacity of the US80 is 80 mm (3.149') ID to max. 406.4 mm (16') OD. The PROTEM US80 is a powerful, robust, reliable and versatile portable tube and pipe beveling and facing machine.

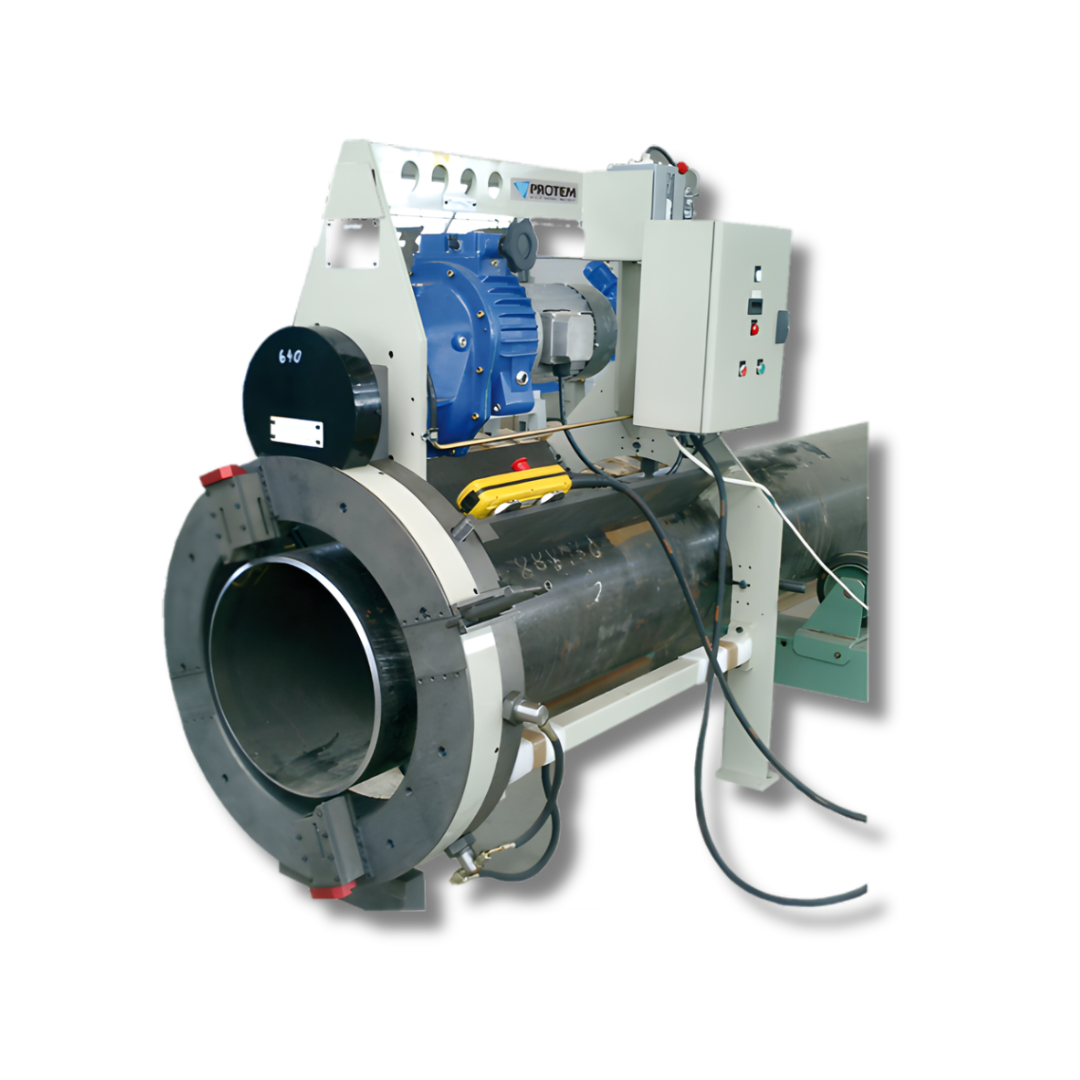

A transportable machine which allow to perform custom bevels from 600 mm (23,622“) up to 1000 mm (39,370“) (version 1) or 1000 mm (39,370“) up to 1500 mm (59,055“) (version 2).

.png)

The machining capacity of the SE219 is 60.3 mm (2.374') to 219.1 mm (8.622'). This tool is ideal for sanitary tubing, food processing and chemical and pharmaceutical applications.

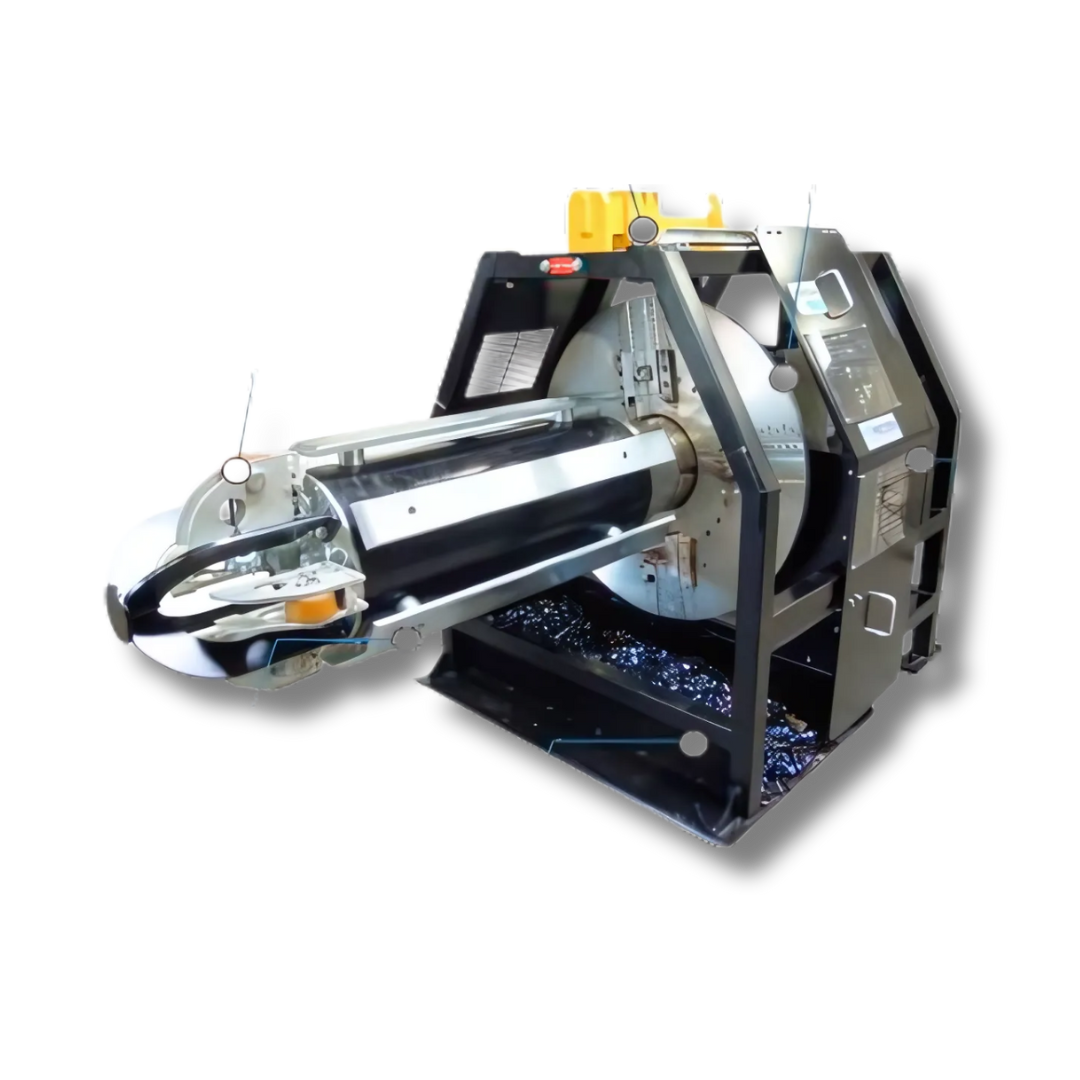

The machining capacity of the BB-24-36 is 609 mm (24') to 914 mm (36'). The BB-24-36 bevel, face and counterbore individually or simultaneously heavy wall pipes.

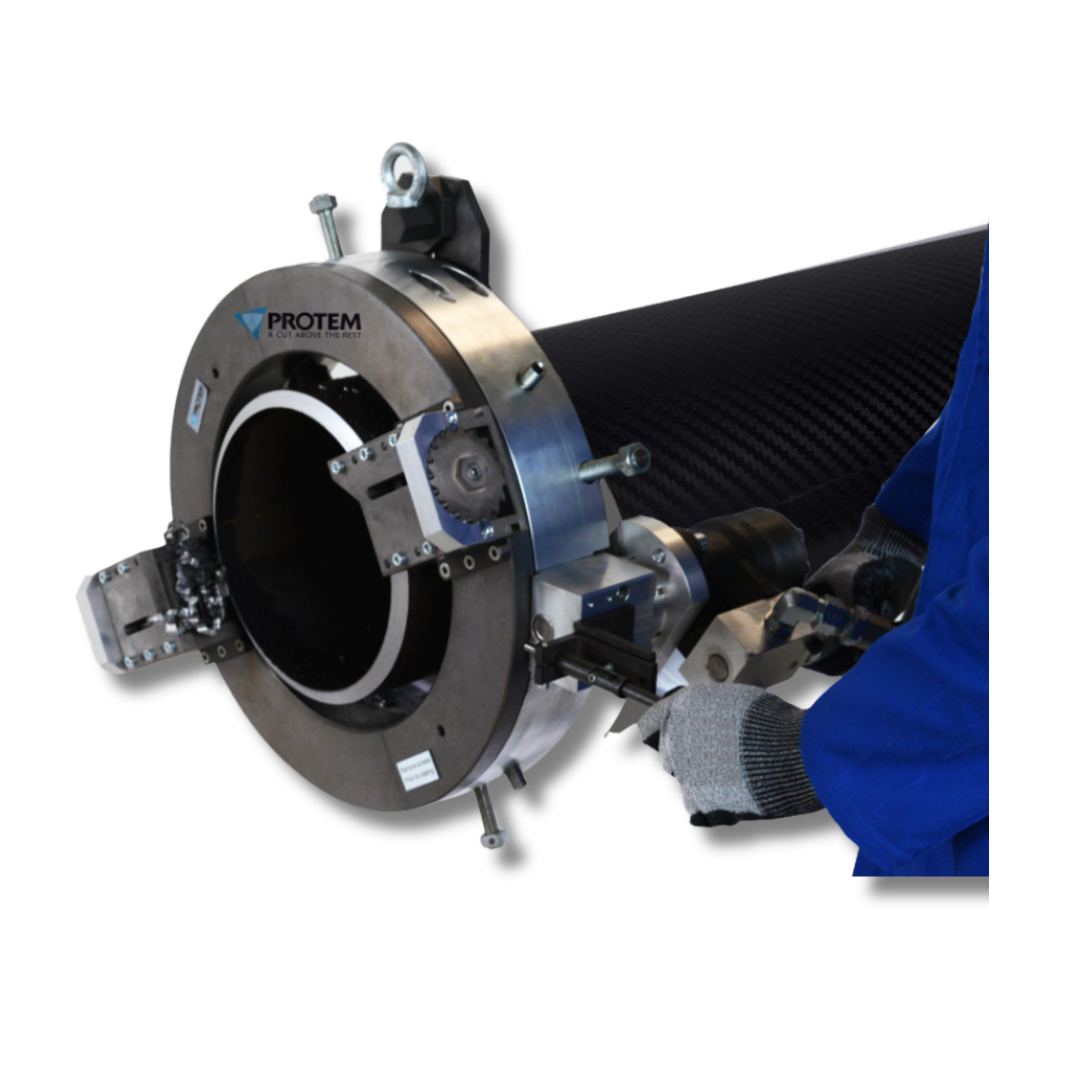

The machining capacity of the TNOFAB-24-36 is 610 mm (24') to 914.4 mm (36'). The TNO is an OD clamping orbital cutting and beveling machine. The cutting tools are rotating around the tube.

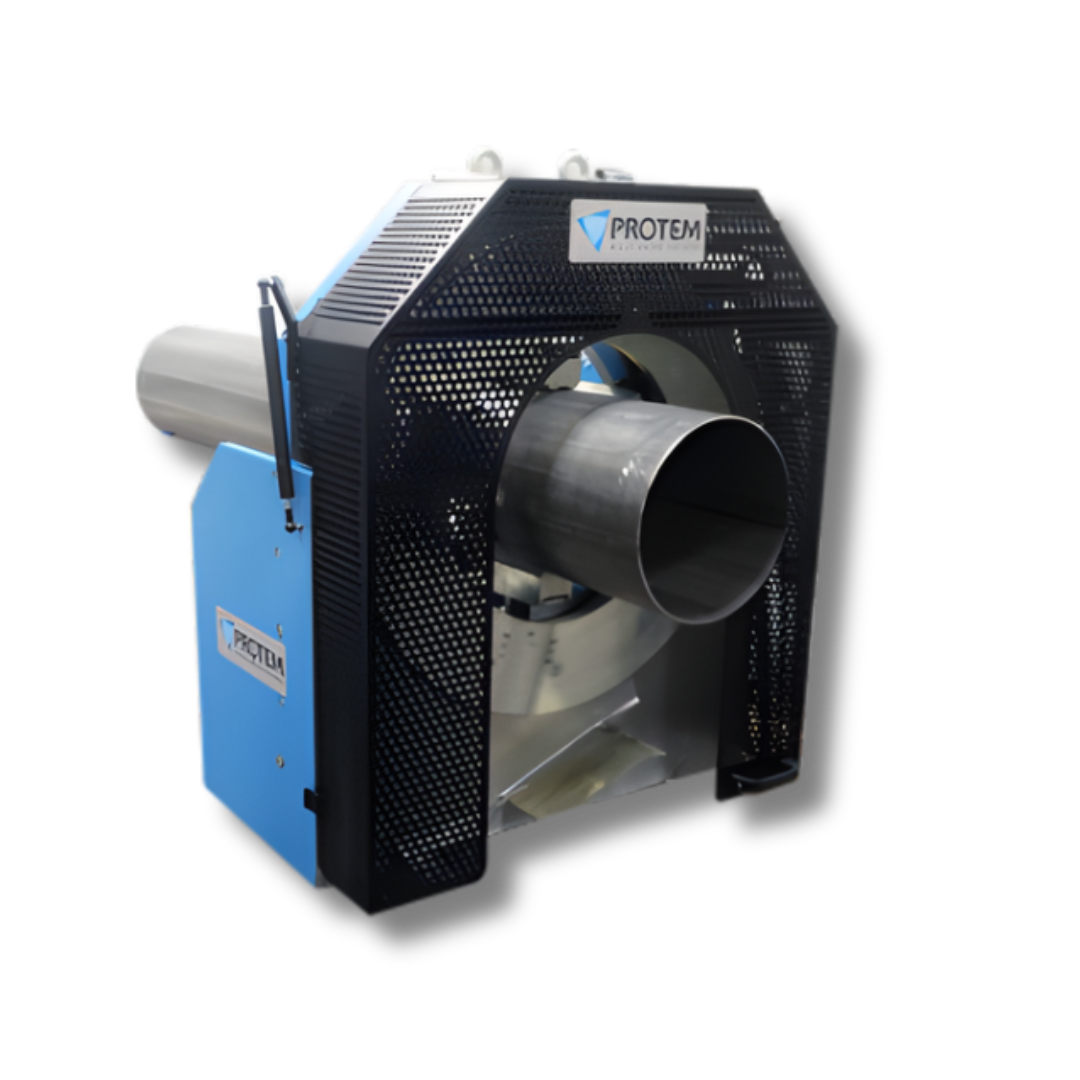

The OCM portable tube cutting machine is designed for cutting and beveling tubes to length from 6" in diameter (Ø168.3 mm) O.D. minimum and for wall thicknesses up to 2" (50.8 mm).

Reliable design and very easy to use, the BMFM219 can performs repeatable quality weld preps on most metal pipes and tubes including carbon and stainless steel, duplex and super duplex, inconel etc. The benefit of these machines is the possibility to machine several tube Ø without changing the clamping system.

The machining capacity of the SE65 is 12.7 mm (0.5') ID to 60.3 mm (2.374“) OD. The OD clamping pipe facing machine clamps on the OD Ø of the tube with clamping collets.

TTNG-machines highlight premium tools for perfect welding preparations. Designed for standard and especially for heavy walls tubes and pipes, for virtually all kind of materials, the TTNG meet the demand for high accuracy on today‘s welding applications.

The machining capacity of the TTNG-LW406 is 273.1 mm (10.751') to 406.4 mm (16'). These machines are the low profile version of the TTNG range. They are mobile and can be opened in 2 halfshells.

The machining capacity of the TTSNG114 is 60.3 mm (2.374') to 114.3 mm (4.5'). The TTS splitframes can be driven either pneumatically or electrically. In line or right angle drive available.

The machining capacity of the TTS-RD60 is 21.3 mm (0.839') to 60.3 mm (2.374'). The TTS-RD machines have been especially developed to cut thin wall tubes from steel and titanium under tight space conditions.

The machining capacity of the PFM-414 is 101.6 mm (4') to 355.6 mm (14'). The PFM - HSB serve all industries where the weld quality is critical and projects must stay on schedule.

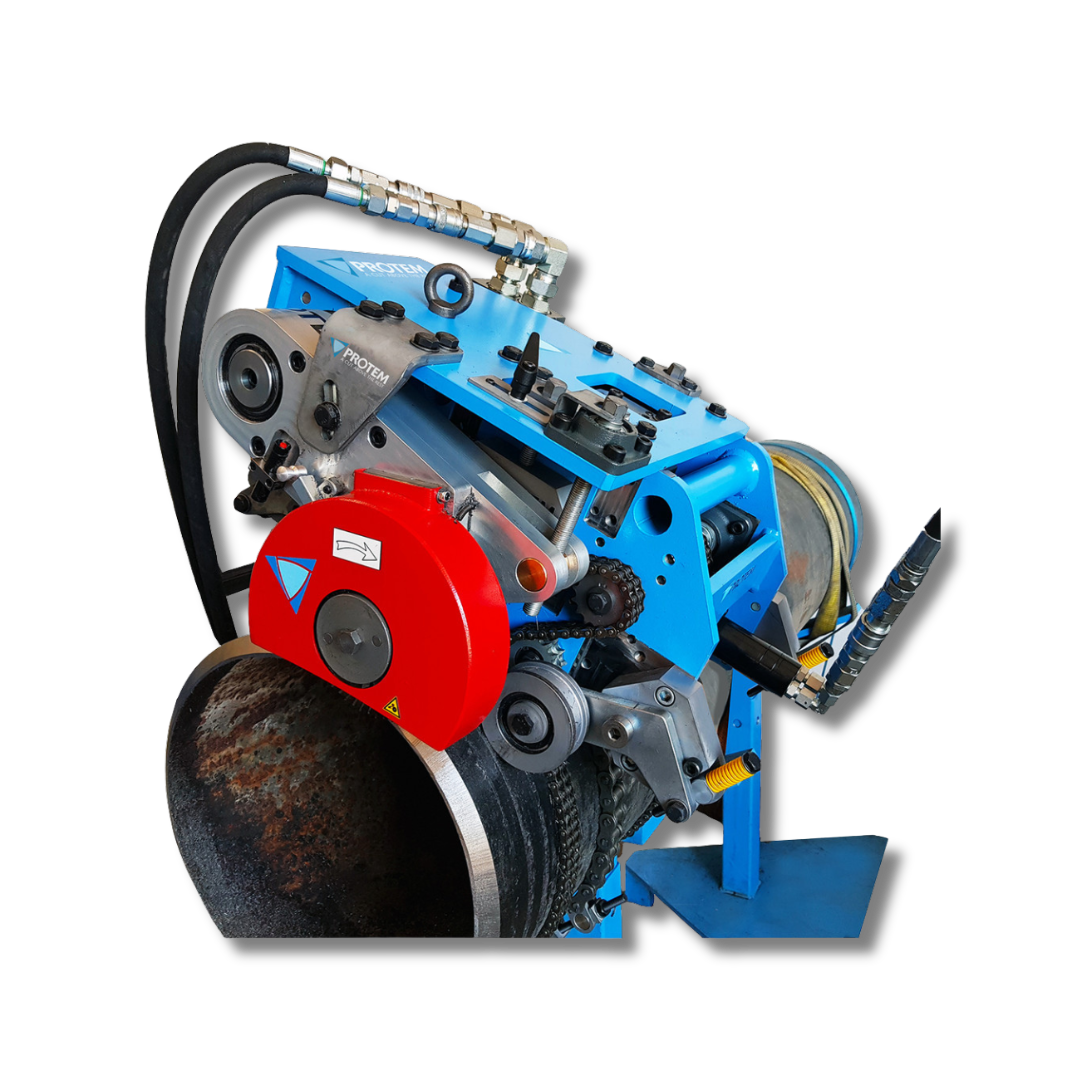

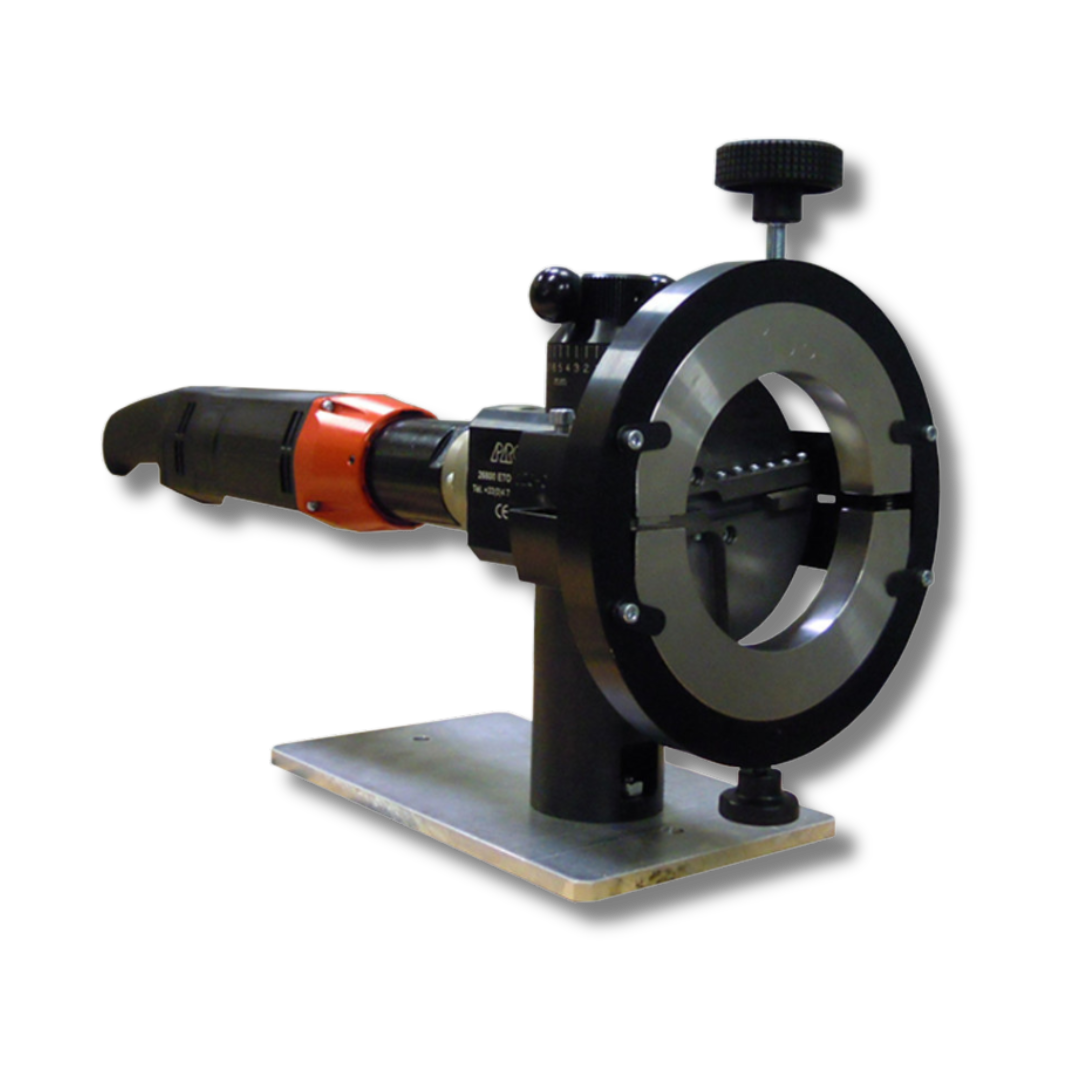

The OHSB is a portable Od mounted tube and pipe beveling and facing machine. The OHSB features an OD clamping system for machining pipes with Ø ranging from 6 to 14’’ OD with wall thicknesses up to 60 mm.

.png)

.png)

Reliable design and very easy to use, the BMFM219 can performs repeatable quality weld preps on most metal pipes and tubes including carbon and stainless steel, duplex and super duplex, inconel etc. The benefit of these machines is the possibility to machine several tube Ø without changing the clamping system.

The machining capacity of the GR40 is 21.3 mm (0.839“) ID to max. 60.3 mm (2.374“) OD. The PROTEM GR40 is specifically designed for boiler panels and waterwall cutout windows.

.png)

The machining capacity of the SL120 is 50 mm (1.968') ID to max. 120 mm (4.724') OD. The SL120 has been especially designed to square tubes, fittings and tees on most metal pipes and tubes including stainless steel.

© 2026 Boltimizer Corporation. All rights reserved.